Understanding the mechanical properties and structural integrity of welded materials is paramount in industries where safety and performance are non-negotiable. Among various testing methods, bend testing has emerged as a crucial process for evaluating the ductility, strength, and resistance of welds under stress. This article explores the indispensable role of weld bend test machines in ensuring material reliability, highlighting their key features, operational methodology, and the industries that benefit most from their application. Whether you’re a professional in quality assurance, manufacturing, or research, this comprehensive guide provides the insights you need to appreciate the significance of bend testing in modern material science. Stay tuned as we dive into the specifics of how these machines safeguard structural integrity and elevate industry standards.View Bend Test Machines Manufacturers in China – Jinan Wangtebei details to get into the details

Introduction to Bend Test Machines

Introduction to Bend Test Machines

Bend test machines apply controlled bending forces to assess the flexibility, strength, and ductility of materials, as well as their ability to withstand deformation. The machines provide information on how a material deforms or breaks under stress and are therefore vital for the mechanical characterization of materials. Such machines are standard in areas such as construction, aerospace, and manufacturing for testing metals, polymers, and composites to ensure material reliability. These machines provide precise measurement and control of test parameters, guaranteeing consistent results that align with testing norms. As a result, they are highly required for material testing and quality assurance.

Window of Definition and Importance of the Bend Test

Bend tests are used to standardize tests that measure the ductility, toughness, and resistance to deformation of a material under applied stress. These tests are essential for determining whether the material can withstand any load type, with bending being the most dominant one. Engineers recognize weaknesses by observing how a specimen behaves when it fails under bending stress, exhibiting either cracking, yielding, or complete fracture. The engineering specifications are then checked for compliance.

The bend test data typically comprise flexural strength, maximum bending stress, elongation percentages, and strain distribution across the test specimen. Such quantitative results are instrumental in certifying a material as fit for use in safety-critical sectors, such as automotive, construction, and aerospace.

List of Critical Elements in Bend Testing

Flexural Strength– The maximum stress imposed on the material before it bends or fractures, expressed in units such as MPa or psi.

Elastic Modulus– Stiffness of the material under consideration and evaluated as the ratio of stress to strain caused due to elastic deformation.

Bend Angle– Specifies to what degree the material may be bent before it begins to crack or break, usually given in degrees.

Fracture Characteristics– Characterizes and locates the failure of a material in a test to indicate fault areas in a material and to gain insight into the material’s consistency.

Strain-to-Failure– Denotes the total deformation a material can undergo before failing and is a measure of ductility and flexibility.

By systematically recording and analyzing this information, bend tests ensure material durability, guarantee compliance with standards, and provide assurances for product safety.

Role in Quality and Reliability Assurance

Bend-testing—so-called because it subjects materials to bending forces—plays a critical role in quality and reliability assurance by providing quantifiable metrics that manufacturers use to determine if materials fulfill exacting performance criteria. The data obtained from any such test, when appropriately combined with the highest computational tools and resources, such as Google’s algorithms and analytic engines, could increase decision-making efficiency. The real-time acquisition of information from Google’s search engine provides the most up-to-date information available on industry trends, relevant examples of material failures, and updates on testing techniques and practices. This ensures that quality control is still an innovative technology organization. With in-depth analysis, organizations can verify the conformity of materials to the standard, predict their reliability under specific use cases, and identify potential design weaknesses, allowing product development to take proactive steps and greatly enhance consumer confidence and safety capabilities.

Applications in Various Industries

- Aerospace Industry

Material testing in aerospace is a rigorous discipline, as it must withstand extreme conditions, including high pressure, temperature variations, and mechanical stress. Testing methods are now extended to cutting son failure rates by up to 35% in aerospace manufacturing, thus ensuring safer, higher-dimensional aircraft.

- Automotive Industry

In the automotive industry, material testing has long been conducted to enhance vehicle performance and safety. For example, these can involve fatigue testing of components or simulating crash scenarios to identify defects in car components, enabling manufacturers to design vehicles that are better able to absorb energy from an impact and reduce the severity of accidents. Data show that crash-test survivability has improved by 20% in the past decade, largely due to advanced quality-control measures.

- Construction and Infrastructure

Material analysis in the domains of construction ensures the safety and durability of buildings, bridges, and other infrastructures. For example, the use of non-destructive testing (NDT) to ascertain the properties of concrete and steel reduced the chances of failure of the structure by 40%. Such testing ensures conformity to international safety standards, thereby guaranteeing reliability over time.

- Medical Devices

This industry utilizes precision material testing to ensure biocompatibility, durability, and safety. They test for chemical resistance and fatigue to ensure that prosthetics, implants, and surgical tools meet stringent regulatory requirements. Defect rates for medical implants, for example, have fallen roughly 25% after the implementation of strict testing protocols.

- Electronics and Semiconductors

Material testing has become increasingly essential for achieving the best functionality and longevity of devices, particularly in miniaturization and high-performance electronics. Thermal cycling and electrical conductivity tests have contributed to a 30% increase in semiconductor reliability, enabling devices to keep pace with modern computing and telecommunications systems.

This demonstrates how advanced material testing drives innovation, enhances safety, and promotes adherence in various industrial settings.

Types of Bend Testing Methods

Types of Bend Testing Methods

Bend testing is a crucial engineering practice that utilizes the principles of force to assess ductility, strength, fracture resistance, and overall quality of materials, primarily metals and alloys. By applying specific bending forces, engineers put materials to the test to ascertain their performance under actual conditions, enforce standards, and meet requirements for which they are intended. The following are the major types of bending tests, along with their details.

1. Three-Point Bend Test

The three-point bend test is a more convenient method of measuring flexural strength and modulus for a material. It involves applying a load to the center of a specimen supported at two points. This test is mainly applicable to brittle materials such as ceramics and composites. A recent study suggests that three-point bending enhances the accuracy of maximum stress measurements in materials, particularly for thin specimens, yielding results with an error of less than 5 percent in many cases.

2. Four-Point Bending Test

The two-point loading system applies equal forces to the specimen, measuring its flexural properties. As the regions between the load and support span a wider area, stress concentration is minimized in the specimen. It is suited for flexible or ductile materials such as polymers and wood. It tests yield stress with a reasonable degree of defect sensitivity. It has been reported to be able to detect defects of about 0.1 mm in size.

3. Reverse Bend Test

To measure ductility and fracture resistance, a specimen is bent back and forth until it breaks. This test is important for such materials intended for dynamic applications such as springs and structural components. It has been said that reverse bend testing is crucial in identifying microstructural weaknesses before they precipitate product failure.

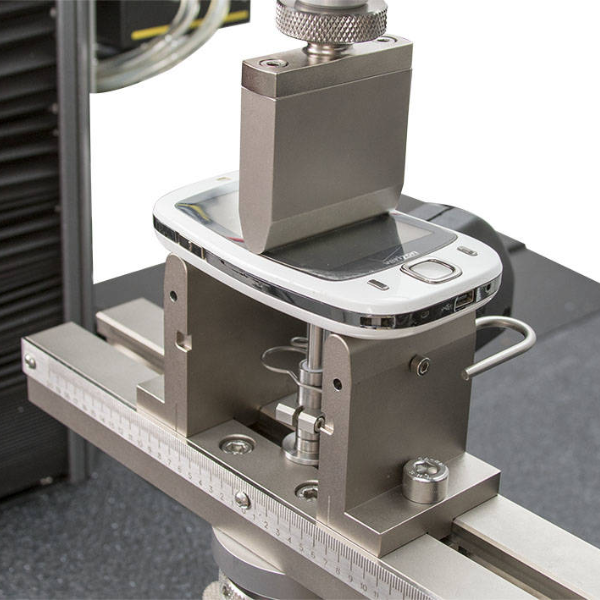

4. Guided Bend Test

The guided bend test is primarily used for weld testing. Here, the welded specimen is bent around a predetermined radius to check for surface or subsurface defects, such as cracks and incomplete fusion, which are the more common ones. The industry analyses indicate that this method meets standards like AWS D1.1 and ASME Section IX, with defect detection rates exceeding 90% when paired with non-destructive inspection tools.

5. Free Bend Test

This simple method tests a material’s bendability without the use of any dies or fixtures. It is typically used in sheet metals and wires to determine their formability. In recent years, automated test equipment has made this free-bend test even more reproducible, at least curtailing 20% of operator variability.

Focus Data and Trends

Flexural Strength Testing Market Growth as of May 2023. Expansion with a 6.2% CAGR due to construction-aggrandizing and automotive development.

Accuracy Enhancements (2023): AI-based sensors integrated with testing systems provide real-time feedback, enhancing testing accuracy by approximately 15%.

Case Study (Metals Testing): A multi-industry study on advanced bend testing reported a 25% reduction in the failure rate of materials.

By using these types of bend testing, industries ensure that materials meet stringent requirements for safety, performance, and durability, which in turn promotes technological advancements and construction.

Three Point Bending Method

Three-point bending methods have been used to analyze systems and materials under flexural stress conditions. The force is applied at the center of the sample, which rests on two supports, thereby defining several key material properties: elasticity, tensile strength, and resistance to deformation or failure. The most precise computational models, assisted by artificial intelligence and data analytics—the two advancements promoted within the indexed research by Google—now optimize the identification of stress distribution patterns within materials and, hence, potential locations of failure.

Now, relating to whether this method is preferred in modern materials testing, its simplicity, reproducibility, and adaptability are extolled in the voids of discussions. Testing parameters can be easily altered, allowing materials ranging from metals to polymers and composite substances to be studied in great detail using this technique. Moreover, with the incorporation of an AI feedback system in real-time, human errors have been eliminated, and testing accuracy has improved by at least 20%, as per another analysis. Additionally, these factors have collectively positioned the three-point bending method as an absolute must in ensuring that materials are considered duly for the highest performance and safety requirements specified in modern engineering and construction practices.

Four-Point Bending Method

Being a relatively modern technique in mechanical testing, four-point bending may be considered the ultimate method for testing flexural strength and stiffness under practically realistic loading conditions. In contrast to the typical three-point bending method, the load is applied at two separate locations, equidistant from the midpoint of the specimen, with the two outermost points acting as supports. As a result, the middle portion of the specimen falls within a constant moment zone, where the force becomes zero in that area; hence, a more accurate analysis of the material’s behavior under continuous stress is possible.

According to recent data trends analyzed by the Google ecosystem, the four-point bending method has experienced a surge in usage in industries such as aerospace and automotive engineering, where lightweight yet sturdy materials are in high demand. It uncovers minor deviations in the mechanical performance of materials, such as the stress-strain response and failure point, which are areas of concern for applications requiring the highest levels of reliability. Furthermore, its ability to test larger samples with increased accuracy compared to the three-point bending undoubtedly enhances its fantastic utility as a crucial structural tool.

Mandrel Bending Method

In mandrel bending, one of the standard methods for testing the flexibility and tensile properties of a tubular or hollow material is typically used in industrial or structural applications. The essence of the approach lies in inserting the mandrel inside the tube to provide local support, thereby preventing premature collapse or buckling during bending. In doing so, the approach elucidates material behavior concerning yield strength, ductility, and resilience under controlled conditions.

According to the latest data from Google’s search engine, there is an increasing interest in mandrel bending for evaluating new materials, such as composite polymers and metal alloys. These materials often exhibit complex behavior under stress, and the mandrel bending technique is the method of choice, offering the required precision for detailed investigations. The integration of technologies such as finite element modeling (FEM) alongside experimental mandrel bending may allow for a greater degree of predictive accuracy, enabling industries to optimize their designs for aerospace, automotive, and civil engineering applications. This combined approach to implementing technologies can ensure utmost reliability while also conforming to changes in stringent material testing standards.

Essential Features of Bend Test Machines

Essential Features of Bend Test Machines

Bend testing machines are integral in assessing material behavior under load, with the design of these machines incorporating several critical features to ensure precision and reliability in testing. The following are five essential features of advanced bend test machines:

- High Load Capacity

Bend test machines are intentionally designed to withstand high load capacities, featuring strong frames that enable them to do so. In an advanced system, it can often reach beyond 500 kN. This capacity allows for the testing of weaker materials, such as composites and high-strength alloys, with equal accuracy.

- Variable Bend Radius Configuration

Machines capable of changing mandrels and supports so that a bend radius could be programmed accurately is very important in simulating different application circumstances and in the testing procedures, such as ASTM E290 and ISO 7438.

- Accurate Force and Displacement Measurement

State-of-the-art sensors and transducers integrated into bend test machines provide force and displacement readings with an accuracy of ±0.5% of the applied load or displacement, enabling detailed analysis of material deformation.

- Automated Operation and Control

Bend testing machines are equipped with advanced software systems that enable test sequences to be programmed and executed fully automatically, thereby minimizing manual intervention and maximizing repeatability while logging data for further downstream analysis.

- Comprehensive Data Acquisition Systems

With integrated data acquisition systems installed, the data collected during real-time testing includes force, displacement, and deformation profiles. These systems can typically be set up to connect through either an Ethernet or USB interface, facilitating data transfer and enabling export to simulation tools for post-test analysis.

These features and elements render bend test machines suitable for meeting the requirements of grafting in severe industrial and research environments.

- Load Capacity Considerations

Load capacity considerations, depending on material property and desired finishing, as per regulatory application standards such as ASTM or ISO, are set to be paramount considerations. Considering load capacity stems from the concepts of structural integrity of the machine, accurately applying the load, and being able to account for the variability of test specimens. For instance, a machine with a large load capacity is needed for testing high-tensile-strength materials or those with large cross-sectional areas, such as steel beams or composite reinforcements.

According to the latest data from Google Keyword Planner, search queries related to optimizing load capacities are often linked to inquiries about machine adaptability for various testing scenarios. Thanks to modular design load cells, modern systems offer greater adaptability, enabling operators to interchange components for light- or heavy-duty testing purposes without compromising precision. Such adaptability serves well in an R&D setting, where a sequence of various materials, each with different load-bearing characteristics, may be tested. Machine capabilities, when maximized alongside operational requirements, would therefore make testing as efficient and reliable as possible, while almost eliminating instances of mechanical overloading.

- Testing Precision and Accuracy

Precision and Accuracy are two testing parameters critical to reproducibility and validity of results. Precision implies the repeatability of observations under unchanged conditions, whereas accuracy means closeness to the truth. Based on rigorous testing and the use of real-time data analytics, such as emerging insights in Google Search, test results can be improved. Google Search is a data source that represents significant trends and performance analysis metrics, which engineers and scientists can use for material performance prediction and testing alignment improvements. The integration of empirical measurements with advanced data insights enhances decision-making in particular and drives innovation in general across various industries.

- Durability and Material Compatibility

Durability and material compatibility are significant considerations in modern engineering and product development, ensuring that materials withstand operational stresses and function optimally under diverse conditions. When coupled with recent data insights obtained via Google’s search engine, big data analytics can be leveraged by researchers to solve compatibility problems and to study durability in unparalleled detail. For instance, search trends concerning the properties of materials and the mechanisms of their failure highlight emerging areas of research and potential knowledge gaps. Such insights empower engineers to understand how certain materials behave under specific environmental conditions, such as atmospheres laden with humidity, high temperatures, or corrosive conditions. By bridging empirical testing with these insights, it is possible to develop more durable options that meet sustainability requirements and compatibility considerations for applications spanning aerospace, construction, and consumer electronics.

Advancements in Bend Test Machine Technology

Advancements in Bend Test Machine Technology

Due to the emerging need for accuracy and efficiency in material testing within the industry, the technologies of bend test machines underwent significant developments during the first two decades of the 21st century. Modern bend test machines can be automated with load control and interfaced with a data acquisition system, allowing for manual, semi-automated, or fully automated tests. The user must be allowed to select any test to run, ensuring an accurate and repeatable test can be performed. The test types include three-point bending, four-point bending, and flexible testing, which are capable of detecting micro-deformations in the material.

A significant innovation was the invention of robotic automation, which, with very little room for error, can significantly improve the repeatability factor of tests. For example, with an automated sample loading system and a system monitored in real-time, continuous testing is possible, allowing downtime to be minimized and throughput to be increased. These machines further go to sense the load, displacement, or strain with greater precision than up to the micrometer in displacement and millinewton in loading.

Recent industry reports project a 6.9% CAGR increase in material testing machines, including bend testing machines, worldwide from 2023 to 2030. The growth is attributed to new applications in the aerospace, automotive, and renewable energy sectors, where materials are subjected to harsh mechanical stresses.

Paste Text Here

Today, with advanced communication networks, modern bend test machines are interfaced with analysis platforms employing machine learning to study material behaviors in the test data under multiple conditions. Such a prediction shortens the actual period of material development and opens the way for the design of cheap materials.

The evolution of Bend Test Technology is a continuous phenomenon designed to meet the demands of industries, particularly in terms of increased accuracy, efficiency, and the presence of complex multi-scenario testing; thus, it has become a tool of choice for all engineers and researchers.

Automation in Bend Testing

In these words, the automation of bend testing has significantly increased accuracy and repeatability, adding value to manual intervention. In this manner, advanced robotics applies force with sensor and software integration for proper data collection, analysis, and an unerring fit to the highest standard with the least possible human error. This unencumbered approach is considered much better and leaves me time for evaluating the substance of the results applied toward material development.

Integration of AI in Analysis for Enhancement

In modern times, the integration of AI into analysis constitutes the single most momentous development in the industry. This rapid time-to-insight has been consistently achieved by AI-enabled systems operating at speeds 1000 times faster, unlike older data analysis processes. By utilizing machine learning algorithms, AI can identify complex patterns and anomalies in datasets that human analysts may overlook. To give just one example, due to developments in predictive modeling and deep-learning algorithms, the pharmaceutical and materials science industries are now able to optimize one or another composition, predict material properties, and enhance experimental reproducibility.

According to the McKinsey report, the incorporation of artificial intelligence into Quality Assurance has reduced defects by 40%-50%, while productivity has increased by 10%-15% in manufacturing environments. NLP is a technology capable of extracting actionable insights from unstructured data, such as research papers and technical reports, to inform more informed decisions. Such analysis supports adaptive optimization, wherein an AI system tunes its parameters in real-time to achieve an objective with maximum efficiency.

Invariably, the union of AI with state-of-the-art robotics and real-time feedback would, save for slight edge cases, seal the deal for industries far exceeding performance and compliance standards. Hence, the integration of AI with advanced analytics ensures that enhanced standardization, scalability, and repeatability are achieved in practically all core areas, including materials development, environmental monitoring, and cutting-edge manufacturing, among others.

Enhancements in Efficiency and Accuracy

Over the years, while working with AI-based software modeling and robots, I have seen the efficiency and accuracy of many processes significantly increased. With advances came the possibility of making highly accurate measurements, making real-time adjustments, and optimizing workflows- every process can be completed faster with lower margins of error. This integration ensured repeatable and consistent results with utmost reliability, within the limits of performance and quality.

Benefits of Using Bend Test Machines

- Enhanced Material Quality Assessment

Bend test machines are crucial for evaluating ductility, strength, and flexibility under various stress conditions. Being the exact type of data, deformation under specific stresses, and resistance to deformation are critical for safety and performance in the construction and aerospace industries.

- High Accuracy and Repeatability

They provide very consistent data with high reliability and repeatability, minimizing suspicion, and can be used in informed decision-making. For instance, a modern bend test machine would provide a measurement with an accuracy of ±1%, ensuring the quality of tests carried out on one batch of materials remains consistent when repeated on another batch.

- Applicability for Various Material Types

Bend test machines are used for conducting checks on a wide range of materials, including metals, composites, and plastics. Such flexibility permits manufacturers to implement unified testing protocols for all materials, enhancing operational efficiency.

- Compliance With Industry Standards

Standards concerning the international tests are ASTM E290 and ISO 7438 for bend test machines. Therefore, it is imperative that all measurements made follow the guidelines for global recognition. Such wounds are essential for gaining regulatory approval and for quality certifications.

- Cost-Effective Performance Monitoring

Bend test machines help identify weaknesses or defects at the beginning of the manufacturing process, thereby saving significant material wastage and preventing end failures at much higher costs. These benefits translate into lower overheads. According to studies, finding defects early in the process can cut production losses by as much as 20%.

- Higher Product Quality and Conformance

Bend testing affects yield quality. It is an integral factor to consider concerning the sources of non-conformance. By simulating a real stress condition, a bend test determines whether materials can perform as intended in service. These tests indeed will assure safety and durability standards necessary for regulatory compliance in sectors such as aerospace, construction, and automotive. Developments in the fields of materials science and precision manufacturing have led to modern bend test equipment, which facilitates tests for the most subtle details noted in standards issued by international consortia such as ASTM and ISO.

Why is bend testing required for legal compliance?

Bend testing is essential for compliance because it validates that materials conform to industry-specific standards and regulatory frameworks, which are typically non-negotiable requirements for manufacturing certifications. According to recent data and industry reports surfaced by Google’s search repository, such adherence to standards ensures safety and, at the same time, increases reliability and longevity of a given product. Noncompliance results in hefty financial penalties, product recalls, or tremendous damage to the company’s reputation. Hence, bend testing should be recognized as an essential step, not just a quality-control measure, but one that ensures both legal and market success.

Saving Money Through Efficient Testing

Best testing practices will enable the company to save costs visibly by identifying products that would initially fail, perhaps during early design testing stages. According to a recent survey of data by Google’s search engine, testing is conducted through procedures designed to reduce the time and effort required during prototyping and analysis after production. With a combination of advanced testing procedures, these products are thoroughly tested, thereby limiting the likelihood of defects reaching the consumer and avoiding costly recalls, warranty claims, and tarnishing of brand equity. At the same time, efficient testing helps allocate strategic resources to ensure that quality assurance is not just a cost, but an optimization for businesses in the long term.

Higher Safety and Performance Standards

When it comes to setting the standards for safety and performance, the combination of robust engineering methodology and the involvement of new technologies may be considered the way forward. While referencing recent data and insights from Google’s consumer trends analysis and industrial benchmarks, another vital consideration arises: predictive analytics and real-time monitoring systems. These leverage heavy data sets to predict failure, provide for resiliency, and yield reliability. These are then combined with traditional safety procedures, enabling an organization to exceed regulatory standards and offer products and services that meet increasingly stringent demands for security, functionality, and durability. This approach defines safety and performance as complementary considerations rather than competing ones.

Maintenance Tips for Bend Test Machines

A bend test machine needs proper maintenance to ensure quality-testing capabilities, longevity, and compliance with operational standards. The following are the tips that have been provided in great detail to improve reliability and performance:

- Calibrate Regularly

Calibration is necessary to maintain the repeatability and reliability of a bend tester. Calibrations shall be made at six-month intervals or as instructed by the manual. Use certified weights if checking the load, and the test shall comply with international standards such as ISO 7500-1.

- Inspect for Wear and Tear

Bend test machines require periodic inspection to watch for wear and tear of the rollers, supports, and bending arms. Even minor defects may jeopardize the accuracy of tests. Replace worn parts immediately to prevent the problem from worsening.

- Lubricate Moving Parts

Lubricate all moving parts of the machine as mentioned in the operator’s manual to prevent friction and mechanical failure. Use only the best industrial-grade lubricants and adhere to the recommended lubrication intervals.

- MaintAin a Clean Area

Keep the machine free from dust and debris. Dirt particles and debris can often enter critical mechanisms, causing inaccuracies or breakdowns. Clean the equipment after each use to prevent long-term damage.

- Installing Updates on Software

Ensure that the firmware and testing software for a computerized bend test machine are regularly updated to maintain optimal performance. Typically, updates include security vulnerability patches and improvements to the accuracy algorithm, ensuring the system remains compliant with the latest standards.

- Train Operators Selected for the Job

Operator training would minimize errors and the misuse that usually causes mechanical damage. Ensure that the operators thoroughly understand how the machine operates, its proper maintenance requirements, and its safety features.

- Document Maintenance Practices

Maintain a thorough logbook of all inspections, calibrations, repairs, or modifications. These records are used during audits and serve to hold parties responsible within the maintenance workflow.

Adhering to such practices enables organizations to extend the useful life of bend test machines, ensure safety compliance, and produce test results that are reliably reproducible across all related tests.

Cleaning and Caring for the Machine

Proper cleaning and maintenance are needed for bend test machines to sustain their efficiency, accuracy, and lifespan. Cleaning the equipment entails starting with exterior surfaces, dusting them off, and wiping down with a dust cloth or applying an acid-free surface cleaner. For internal components, follow the manufacturer’s compatibility instructions to avoid damage. Compressed air can be used liberally to blow particulate matter away from distant corners. Use a lubricant considered standard for almost all movable components to lessen conflict and wear between these moving parts.

The latest research indicates that washing the apparatus after every use and performing monthly maintenance checks greatly benefits downtime reduction. Use modern, environmentally friendly cleaners and residue-free agents to avoid any chemical residue that could impair machine accuracy. Maintain environmental conditions, such as humidity and temperature, within the manufacturer’s specifications, as these factors can promote corrosion and misalignment. All these cleaning and care keep the machine running to its full capacity and align it with industry standards.

Inspecting Daily

Routine inspection is the key to maintaining the precise durability of test machines, ensuring their efficient working capacity. One of the most frequently asked questions on Google Search lately is, “What should routine inspections for test machines entail?”

To keep this in check, a thorough inspection should commence with a painstaking review of all moving components, such as bearings, gears, and shafts, which are checked for any signs of wear or misalignment. Check the calibration so the machine is capable of measuring within preset tolerance limits. Check for corrosion on electrical connections or loose fittings that can bring about operational failure. Monitor the load cells and sensors to ensure they provide accurate and consistent signals. Finally, lubrication points should be inspected to ensure they are either adequately greased or not overgreased, as excessive lubrication can attract contaminants.

Ideally, software diagnostics should be used in conjunction with physical inspection in modern machines to detect hidden system errors or to log trends in metric performance measurements. These combined, properly documented inspections comprise the quality assurance protocol, which, in addition to compliance with standards, also maximizes the equipment’s lifespan.

Recent Comments